|

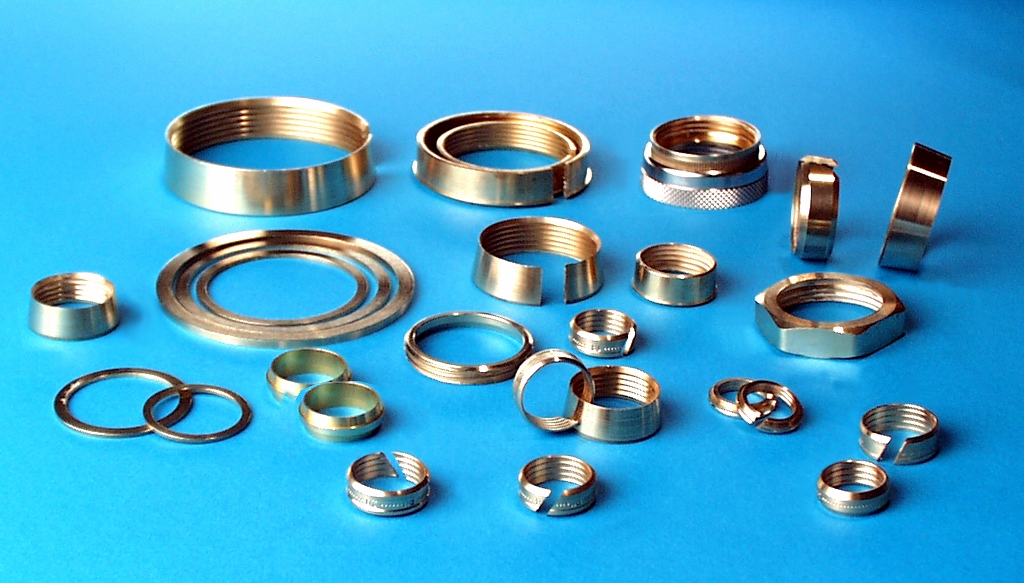

With our company we are today a leaders company in Italy for the production of turned brass parts with hghly qualified staff and solid skills in the sector .

We are distinguished by flexibility and speed

of production .

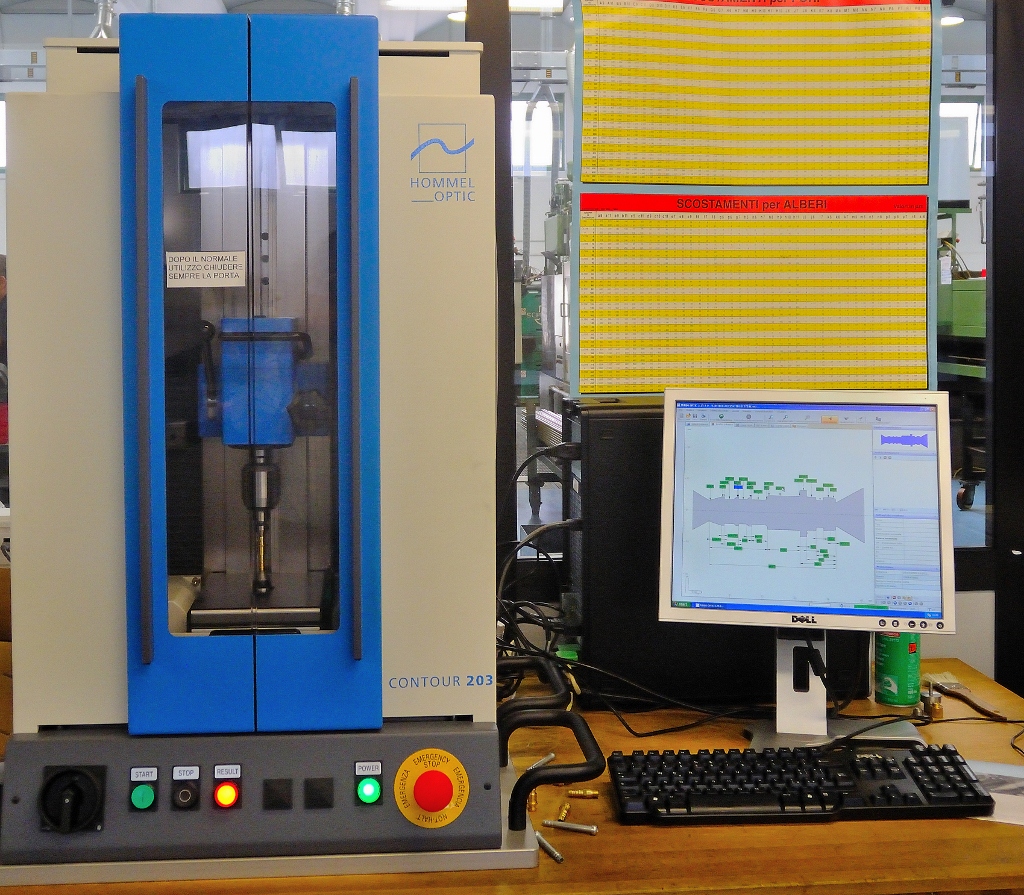

Certification, feasibility studies, process control, traceability of materials and continuousresearches into improvement are the guarantee of the work of our companies .

All Brescian companies the strategic hub of Italian turneries,

we are known in the Italian and foreign market .

We export more than 60% of our production

We produce more than

400 million pieces per year

with 90 multi-spindle lathes

and 12 CNC machines

Our activities:

• Turning

Outsourced services:

• Protective treatments

(nickel plating, chrome plating,

galvanizing, anodizing and other

treatments on request)

• Heat treatments

(annealing, stress relieving, pickling

and passivation)

• Surface treatments

(brushing, lapping and mirrorpolishing)

|